Godel Farms was featured on Agribusiness How It Works’ Youtube Channel. It’s a great update on the progress of the farm aside from our efforts related to cacao and cacao post harvest.

After fermentation, the cacao beans are sun-dried to 7-7.5% moisture content.

Our first try at Godel farms in Amadeo to ferment has been quite challenging due to the very small quantity of wet beans. From 26kg of wet beans, the yield was around 8.8kg of unsorted, dried beans. That’s only about 33.85%

It was also raining for the past few days in the farm. Therefore, we had to use an oven to dry them on the 6th day.

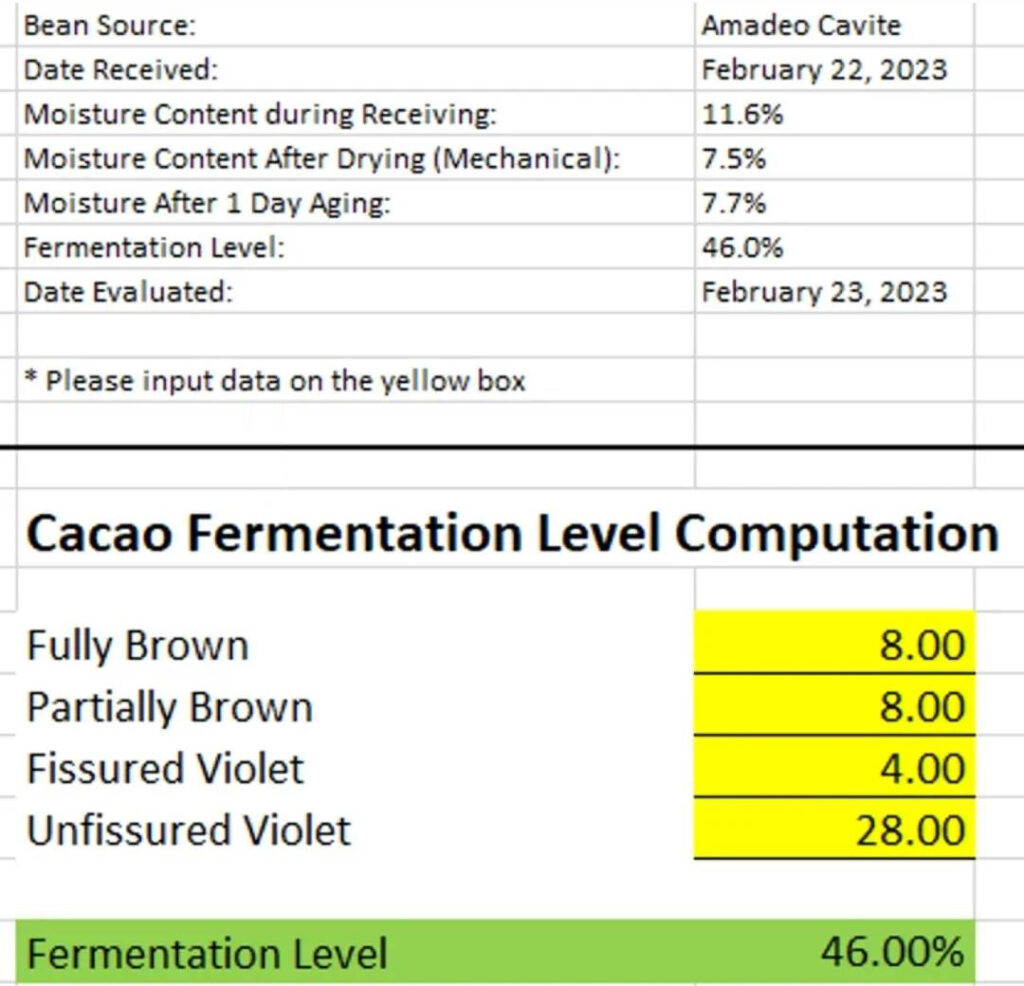

As for cacao grading, these are the results of the cut test:

6th Day of Fermentation

This means the wet beans have gone through 48 hours – 48 – 24 – 24. The last will be 18 more hours. The goal is to have fully brown 100% fermentation, which is impossible. But hopefully, we’ve done enough to be as close as possible.

Learnings from Fermenting Cacao

The great thing about fermentation is that it’s like beer where you need the alcohol, like bread where you need the CO2 to make it rise and like vinegar where you need the acetic acid, plus flavor. It is all the same except you are just getting what you need for that certain product.

SIMPLE SUGAR + YEAST (instant or naturally from environment) + ENZYMES (to work with disaccharide (refined sugar) or more complex carbohydrates) while working within a certain TIME, TEMPERATURE and HUMIDITY, plus AEROBIC and ANAEROBIC FERMENTATION

Which makes…

LACTIC ACID (yoghurt flavor)

ACETIC ACID (vinegar)

CARBON DIOXIDE (gas)

ALCOHOL

and FLAVORS that come from the chemical reaction that results to color change and others.

With cacao, maybe we don’t need to keep the acid, CO2 and alcohol unlike vinegar, bread and alcohol. The most important part is stopping germination, achieving flavor and change in color (chocolatey, fully brown).

Due to the cost of technology, it is not practical to invest on climate-controlled, stainless steel post processing and warehouse. This is for the simple reason that we don’t want our chocolate to be too expensive. The reality is only a few can buy luxury chocolates. Mass production chocolate makers will still look for the cheapest possible source with the highest quality. Unless you go niche, there will be most likely be no return on investment.

Next… DRYING.

Wet Beans Buying in Amadeo, Cavite

We just conducted our first buying of wet beans in Amadeo. Only 2 farmers had harvests for a total of 26kg.

One batch at 14 brix — perfect ripeness for fermentation. The other batch was at 16 brix.

Started February 10, 2023, 3:20pm | Temperature: 26°C, outside temperature at 27°C | pH: 7.5

We made a small square ferment. Skin was easy to remove and the taste of the bean was so astringent and grassy but generally pleasant.

Cacao Fermentation After 48 Hours

Temperature: 34.2°C with 31°C outside box.

We are making 48 hours – 48 – 24 – 24 ferment. Due to the 26kg volume of wet beans, it is difficult to reach a higher temperature.

By this stage, the cotyledons are separating and the radicle are changing color. It looks like there’s a day delay due to the small batch; but it’s okay.

It’s considered a good start even if we don’t have enough beans.

Fermenting After 48 + 48 hours

A sweet-sour smell and alcohol. Beans taste less astringent and bitter. Some flavors are now developing.

Center and side temperatures are almost the same at 44°C versus 43°C.

Radicle is now same the color as the cotyledon. Cotyledon has a light purple color with slimy mucilage.

We mixed the beans and prepared new banana leaves.

There will be 2 more days of 24+24.

One of the purposes of fermenting cacao beans is to stop germination. We are now at the aerobic stage as we mix to let oxygen in; and this will generate more acetic acid, which hopefully balances with the alcohol.

So far, we have discovered 5 cacao trees in the farm. All efforts are now being made to rejuvenate them. One has been identified as a criollo.

The next step is to get scions from these trees and use them for grafting in order to prevent problems in the future. They should be quite resistant to the area already.

We are hoping for the best.

The story of Godel Farms has begun.

On April 7, 2022, we confirmed that one of the five cacao trees found on our Amadeo, Cavite farm is criollo. This one tree is enough to propagate into 5000 trees through grafting. Hopefully, we will be blessed and we can multiply it successfully.

Since it has survived all these years, it has adapted well with the location and the weather. We hope to learn more in the next few years.